Services

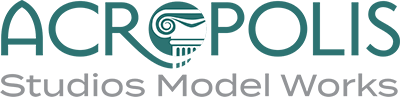

Commissioned Work

When a special event commemoration or custom product solution is required, Acropolis Studios provides a complete range of services from design to production of a presentation-ready product. Acropolis Studios can help with the development of any type of special products.

Drawing from the wide variety of materials, technology and artistic processes available, the possibilities are limited only by imagination.

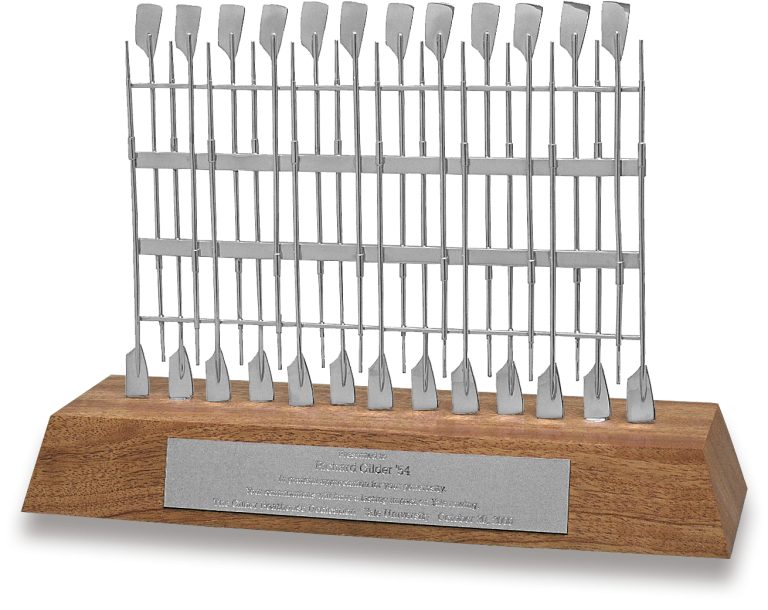

Architectural Modeling

From 3D printing of detail components to complete builds of scale structures, 3-dimensional models are the best way for clients to visualize design concepts.

Our architectural models combine finely detailed 3D prints in a broad range of modern materials in numerous colors, with traditional model making techniques to produce a single channel resource for architectural modeling services.

For more information on architectural printing, visit Acropolis3DPrinting.com.

RTV Molding and Casting

Acropolis Studios’ in-house, RTV molding service supports both resin casting and wax pattern production. Our casting technology produces high-precision reproductions in a variety of materials and colors. Using a custom-engineered wax-injection system, Acropolis Studios provides quality wax patterns for lost wax and foundry casting, affording production of a superior final product

Historical Reproduction

Accurate reproduction of a vintage or historic object requires a knowledge of era-specific manufacturing techniques. This understanding of historical techniques and sensitivity to design details, combined with keen knowledge of processes that allow Acropolis Studios’ historical reproductions to be of the highest integrity and respect of the original component.

Short Run Manufacturing

Acropolis Studios offers short-run production services using our in-house, precision milling machines, several types of 3D Printers, resin casting or pewter spin-casting. Whether you require a small production run, a prototype run to test production concepts or a limited production sales sample line in advance of full production, we can fulfill your short run production needs.

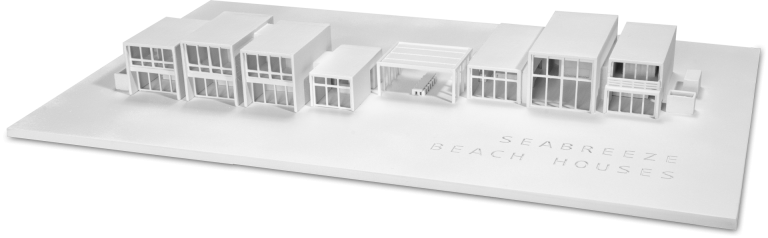

Injection Molds

Acropolis Studios uses our CAD systems and high-precision milling equipment to cut molds into various high-strength materials such as brass and aluminum. A light-weight, durable polymer is available as an optional base material to reduce the weight of larger mold blocks.

The accuracy our computer-controlled cutting process allows mold components to be interchanged which reduces overall tooling expense.

Graphite Electrodes and Tooling Files

Acropolis Studios provides a complete development cycle designed to simplify and expedite the movement from product concept to production ready steel tooling.

Acropolis Studios employs a 4-step process to assist steel die work. Our process eliminates redundancies between the design, sample and tooling departments by creating an accurate, 3D prototype of the final part for approval before the first steel tool is milled.

Step One

Design Development and Digital Illustration

Working from your project specifications, the product is digitally constructed. Manufacturing concerns that affect appearance, such as release angles and tool durability, are accurately represented.

Step Two

Approval Model

Plastic prototypes can be quickly generated using cutting tools identical to those used for final steel milling. The ability to evaluate and adjust this exact representation before steel work eliminates expensive retooling.

Step Three

CNC Milling Files

Once finalized and approved, the digital files transfer to the toolmaker as a mesh file or as G-Code files. Our software post-processes to the most popular mill specifications ensuring compatibility.

Step Four

Graphite Electrodes

As an alternative to CNC milling files, Acropolis Studios provides graphite electrodes, keyed to your specifications in POCO-EDM C3. With the precision and repeatability of our computer-controlled cutting, multiple electrodes are accurately produced.

Froggie Board

Froggie Board is a high visibility modeling board, manufactured and distributed exclusively by Acropolis Studios, providing ease of machining and the ability to go direct to vulcanized rubber molds.

For more details, visit: www.froggieboard.com